Exploring advanced epoxy solutions for reliable low-power instruments transformers

How can epoxy be engineered to be stronger and more reliable?

At SuperGrid Institute, our engineers challenge standard formulations and test materials under extreme conditions to understand how they perform in the toughest environments.

SuperGrid Institute is tackling key challenges in material development for the high voltage industry, particularly ageing, reliability and property optimisation. Through innovative formulations and rigorous testing, we help clients identify alternatives to standard epoxies and understand how materials perform over time.

Its expertise covers every stage of research, from small-scale material testing to full-size components, ensuring results are directly applicable to real-world conditions.

Tackling sensor challenges

G&W Electric, a leading U.S. manufacturer of innovative power grid solutions and products with subsidiaries in Europe, is collaborating with the SuperGrid Institute to develop new approaches for assessing product aging.

G&W has designed, developed and deployed innovative voltage and current sensors technology based on highly innovative, customisable, high-precision low power instrument transformers (LPITs) for real-time management and diagnosis of energy distribution on both overhead and underground lines for the grid of the future. These sensors are used in a wide range of environments, from arid regions to tropical climates, and must demonstrate consistent reliability regardless of external conditions. We assessed various epoxy systems under humid conditions to better understand ageing mechanisms and identify opportunities for formulation optimisation.

Testing and improving epoxy performance

This study was structured around two parameters:

- Formulation improvements – special treated fillers were introduced into the epoxy to enhance its mechanical and dielectric performance.

- Design innovations– a reference material with an innovative shape, combined with a surface treatment, was tested to improve resistance to water absorption.

To validate these approaches, a robust methodology was established through ageing trials simulating a variety of environmental stresses:

- High-temperature, high-humidity climatic conditions

- High-temperature, low-humidity climatic conditions

- Low-temperature, high-humidity climatic conditions

This study has allowed multiple epoxy systems to be benchmarked. One material in particular demonstrated superior stability and resistance to hygrothermal ageing, supporting improved sensor reliability.

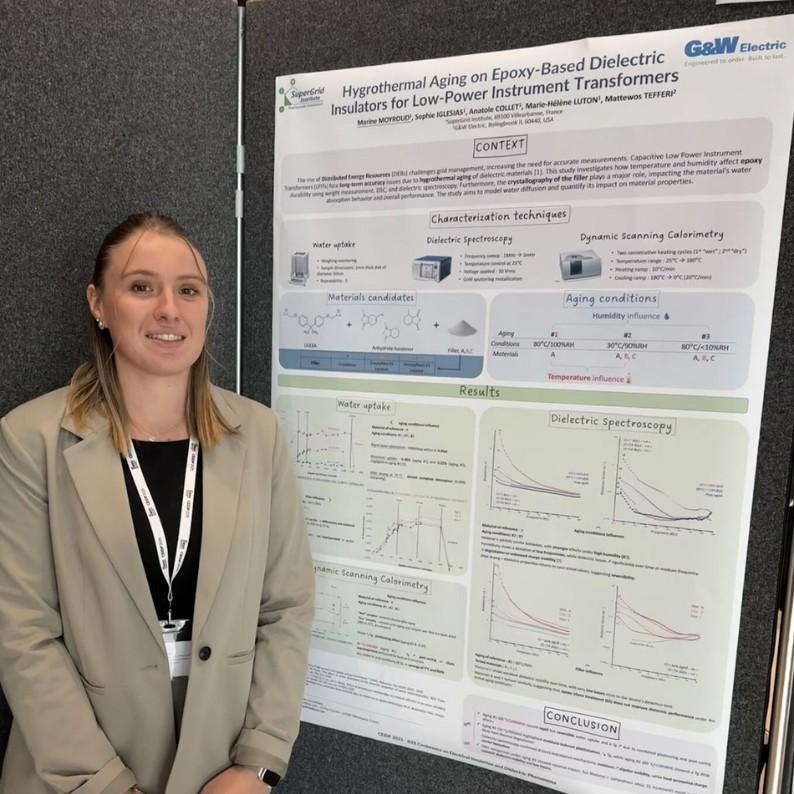

Spreading knowledge and expertise

To present the findings of this case study with G&W Electric Co., Marine Moyroud presented a paper at the IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), in September 2025.

The paper titled “Hygrothermal ageing on epoxy-based dielecric insluators for low-power instrument transformers”, focuses on both the methodology and material characteristics. The work has also benefited from the contributions of Sophie Iglesias, Anatole Collet, Marie-Hélène Luton from SuperGrid Institute, and Mattewos Tefferi from G&W Electric company.

Towards a more resilient future

SuperGrid Institute’s work covers every stage of the process, from small scale tests to full size testing. This approach enables the team to characterise epoxy ageing under a wide range of conditions: including extreme heat, high humidity and dry environments.

By combining access to multiple material suppliers, advanced characterisation techniques, and full-scale testing facilities, the Institute demonstrates its ability to provide complete, reliable studies on material ageing. This gives clients confidence in the long-term performance of their products and supports industry efforts towards a more sustainable and resilient formulations.