The SiCRET + project: understanding & preventing

the ageing of SiC modules

Three years after the launch of the initial SiCRET project, SiCRET+, a project which began in October 2023, is extending the scope of its study to include silicon carbide (SiC) power modules. The aim is to understand the ageing of power modules in normal and degraded operation, and in harsh environments (temperature, humidity, radiation), in order to derive predictive ageing models.

A multi-sector project co-piloted by an ITE and an IRT

This ambitious €6.7 million project brings together a multi-sector consortium comprising players from the aviation (Safran, Airbus, Liebherr), rail (Alstom), automotive (Valeo, Vitesco), space (Airbus Defense & Space) and energy (Schneider Electric) sectors, as well as research laboratories and institutes (SATIE, AMPERE, IMS, ICAM, SuperGrid Institute).

The SiCRET+ project is co-piloted by the Institute for Energy Transition (ITE) SuperGrid Institute and the Institute for Technological Research (IRT) Saint Exupéry, both members of the FIT Association (French Institute of Technology).

Reminder of the SiCRET project (2020 – 2023)

The SICRET project was the first French public-private initiative on a national and European scale entirely dedicated to the reliability of It brought together the main industrial players in the energy transition value chain, as well as the best laboratories in the field. Thanks to the technical and scientific quality of the consortium, the project was able to attract leading power electronics suppliers such as STMicroelectronics (EU), MITSUBISHI (Japan), Infineon (EU), Rohm (Japan) and Wolfspeed (USA).

In a context of massive electrification of land and air mobility, where the weight and volume of electrical equipment are crucial, this technology, with its exceptional thermal and electrical performance, offers a real alternative to conventional solutions based on silicon technology. It significantly reduces the volume and weight of electrical equipment. However, the adoption of this technology is limited at present because of questions about its reliability in use, due to a lack of long-term data and sufficient knowledge about its main degradation mechanisms. To provide answers, the project developed new test methodologies capable of identifying the main degradation and failure modes of SiC MOSFET switches.

Three years after its launch, the project has helped to structure the scientific and industrial ecosystem, providing considerable added value in terms of knowledge transfer and industrial best practices. The value of these achievements is widely recognised by national and international standardisation bodies in the field of power electronics (JEDEC2, AEC3, ECPE4, CFF5, etc.).

SiCRET +: beyond the electronic chip

The ecosystem put in place for SICRET has been strengthened and extended for the next stage of the project, SICRET+, whose scope extends to SiC power modules.

“The main difference with the SiCRET project lies in the change in the object of study: the chip previously studied on its own is now considered in its immediate environment (the module), enabling us to study its ageing in real operation. We are taking advantage of the knowledge acquired about chip ageing during the SiCRET project, while at the same time examining whether the same mechanisms appear during module ageing, or whether new ones emerge”.

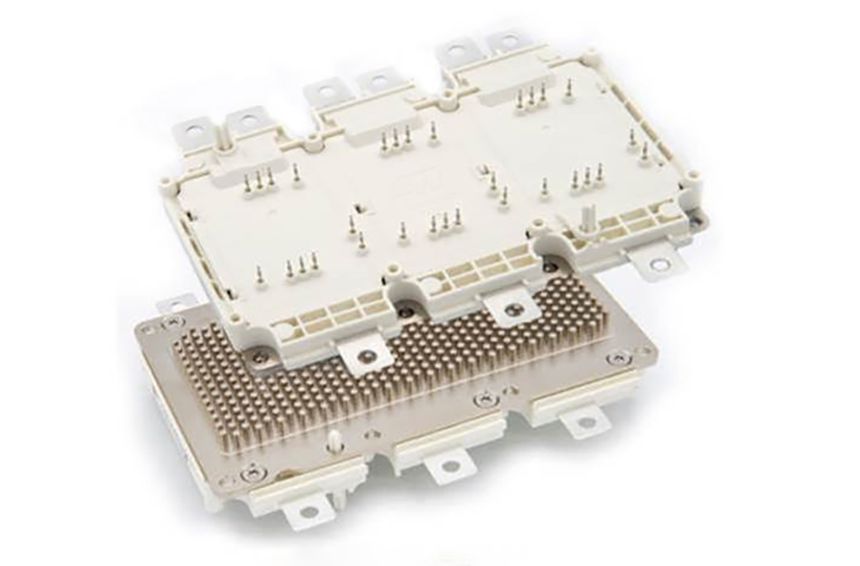

Picture: ST Microelectronics ACEPACK Drive Module

The 3 objectives of the SiCRET+ project

- Understanding the ageing of SiC power modules in harsh environments

To understand the behaviour of power modules based on SiC components, are being undertaken. This standard test, which involves switching the modules for several hundred or thousand hours until they fail, will be studied on its own, but also in conjunction with other constraints such as the presence of high humidity, to see how such severe environmental conditions affect the ageing of the module.

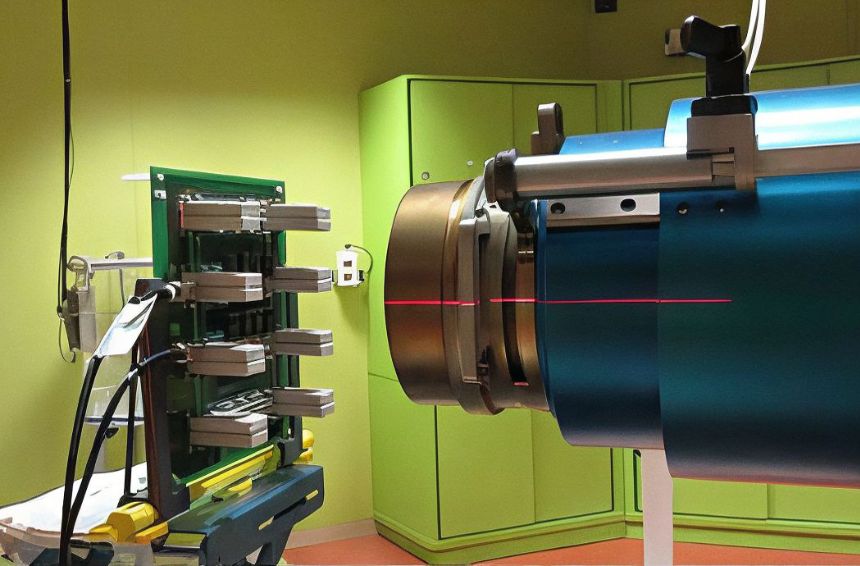

The influence of cosmic radiation is also being studied. Although barely present at ground level, this radiation is significant at high altitudes, such as on aircraft, and even more so in space, on satellites for example.

- Improving the use of parallel chips

SiC chip designers face difficulties in producing large chips capable of carrying high currents. They get round this limitation by using several smaller chips in parallel. Unfortunately, these chips can vary slightly, even if they come from the same supplier, resulting in switching discrepancies and potential long-term damage leading to a shorter lifetime for the module compared to the individual chips.

The project therefore focuses in a module, both for normal use and for abnormal situations such as short circuits and other abnormal modes of operation that the modules must be able to withstand. The project aims to develop an understanding of the behaviour of chips in parallel, both in the case of balanced chips, but especially in the case of unbalanced chips, whether these imbalances appear at the beginning of their life or emerge as a result of differential ageing, and to develop appropriate test methodologies. This work should enable end-users to define optimum chip selection and sorting criteria to ensure that modules’ lifetimes are long enough for each application.

- Working towards a predictive ageing model

Various tests and test methodologies are being implemented as part of these activities and applied to modules from different suppliers to ensure that they are suitable for the different SiC module technologies on offer. In addition to the quantitative measurement of module lifespan, the aim, which is of particular interest to end users, is also to create ageing models that take into account the specific usage profile of each application, as well as the environment in which the module evolves. In this way, manufacturers will be able to anticipate the number of switches expected for a given chip, and hence its lifespan.

The project’s tests are mainly being carried out at the SATIE and Ampère laboratories, SuperGrid Institute, ALTER and at the IRT Saint Exupéry.

Picture: High-energy pronton beam test card at the Centre de Protonthérapie d’Orsay

New collaborations

“The SiCRET and SiCRET+ projects have paved the way for new collaborations with international standardisation and research bodies such as the ECPE (European Center for Power Electronics). This is an important step in the recognition the IRT Saint Exupéry’s teams’ work.”

The SiCRET+ project teams hope to have an impact on the future standards adopted for SiC chips and modules at the end of the project by submitting their results to certification bodies.

An ITE-IRT collaboration

The SiCRET project paved the way for an official collaboration between SuperGrid Institute (ITE) and IRT Saint Exupéry, even before the creation of FIT. Thanks to their complementary expertise, IRT Saint Exupéry’s in energy conversion for mobility and SuperGrid Institute’s in the transport of electrical energy, the two institutes succeeded in assessing the reliability of SiC MOSFET chips, establishing aging laws and contributing to the standardisation of test protocols for medium (1.2 kV for IRT Saint Exupéry) and high voltage (3.3 kV for SuperGrid Institute) components.

Thanks to this collaboration, a French ecosystem was born around transport in its broadest sense, be it for mobility or the transport of energy. This helped achieve a critical mass that convinced European and global power semiconductor (SiC) manufacturers to discuss their technologies and test methods for the qualification of their components’ reliability.

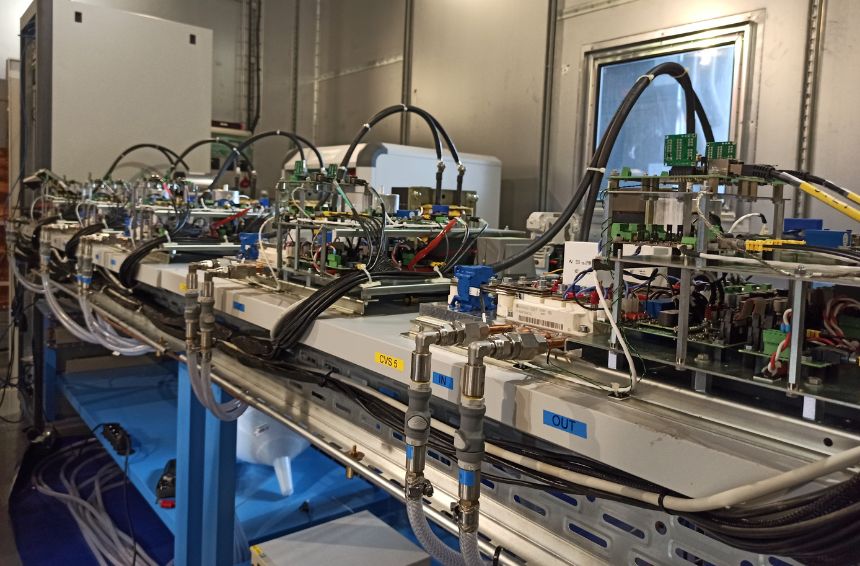

The SiCRET+ project continues and strengthens this collaborative initiative with additional industrial actors interested in the reliability SiC MOSFET modules. SuperGrid Institute is actively involved in organising the project and planning its tasks, as well as coordinating actions with semiconductor manufacturers. In addition, SuperGrid Institute is making an active contribution to the project by setting up dedicated test benches to assess the reliability of the SiC MOSFET modules under power cycling conditions. These state-of-the-art test benches will be used to generate accelerated ageing and will help establish aging laws and mitigation strategies to enable manufacturers to optimise the lifespan of converters and reduce their carbon footprint.

SuperGrid Institute’s IGBT ageing bench with thermal cycling © SuperGrid Institute