Insulation materials

Enhance electrical insulation reliability & accelerate your innovation cycle

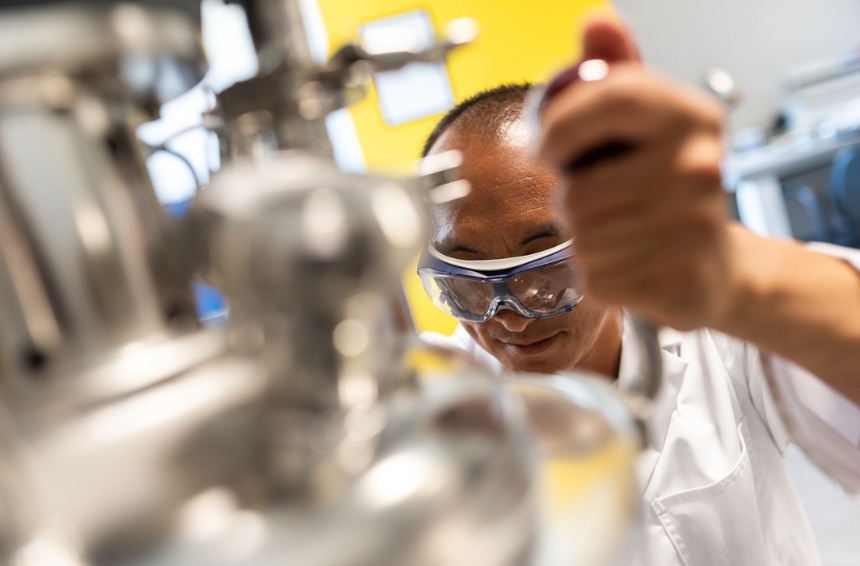

SuperGrid Institute’s material laboratory brings together a unique set of prototyping and testing assets, from state-of-the art analysis capabilities to advanced in-house set-ups dedicated for advanced electrical characterisation.

Drawing on a team of experts in dielectrics for AC and DC applications, we offer a full range of services to tackle dielectric material investigation, characterisation and qualification as well as insulation design and testing.

Where needed our high voltage test platforms are made available to push the limits of material investigation.

Our references

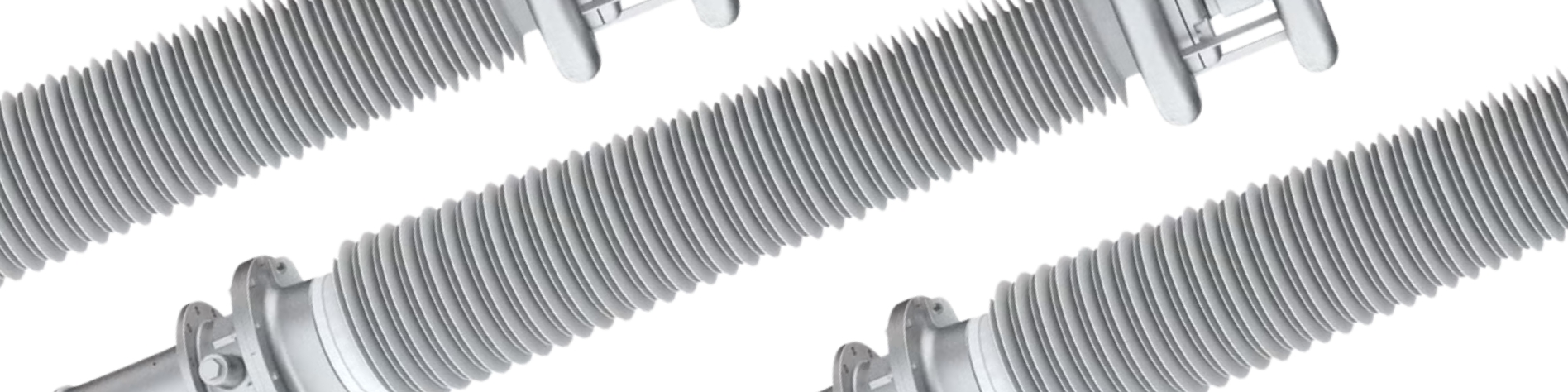

Evaluating 640 kV DC SF6-free cable terminations with Prysmian

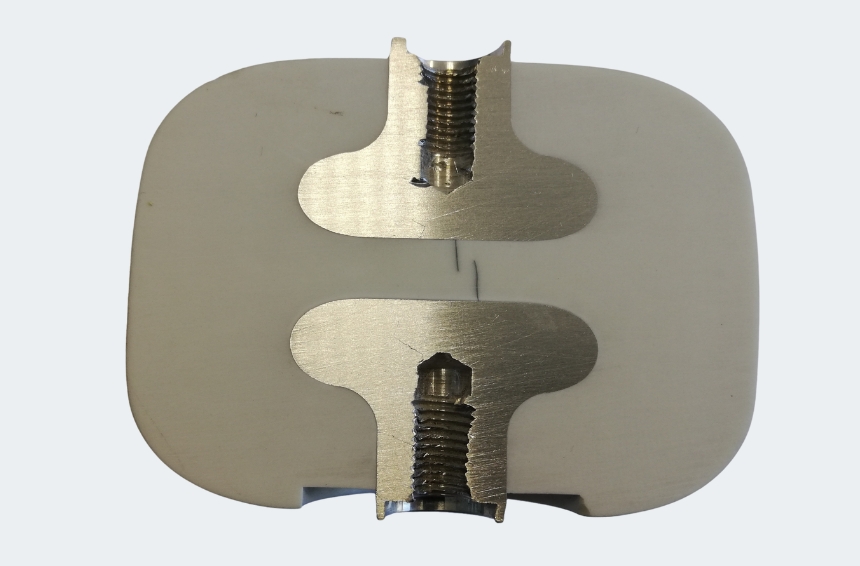

Prysmian, a global leader in cable solutions for energy transition and digital transformation, needed to select the best material combination for its brand new HVDC epoxy-insulated cable terminations. These terminations are a complex arrangement of materials that ensure the safe connection of HVDC cables to GIS.

Multiple epoxy samples were tested simultaneously by our material testing department under different conditions including humidity, temperature & voltage stresses.

Advanced epoxy solutions for low-power instrument transformers

The trials identified a high-performance epoxy system with superior resistance to environmental stresses, supporting improved sensor reliability and faster material validation for grid equipment manufacturers.

Material sampling and prototyping

Our chemical laboratory is used to prepare samples, prototypes and guarantee the highest quality of the insulating materials.

Our team of experts have an acute understanding of sample design and shaping, from the design and verification phase using CAD to material production processes (gravitational injection, impregnation).

Physicochemical

& mechanical analysis

Our capabilities include:

- Infra-red spectroscopy (FTIR)

- Differential scanning calorimetry (DSC)

- Thermal conductivity

- Dilatometry

- Viscometry

- State-of-the art mechanical test benches: tension, compression, bending…

Advanced electrical characterisation

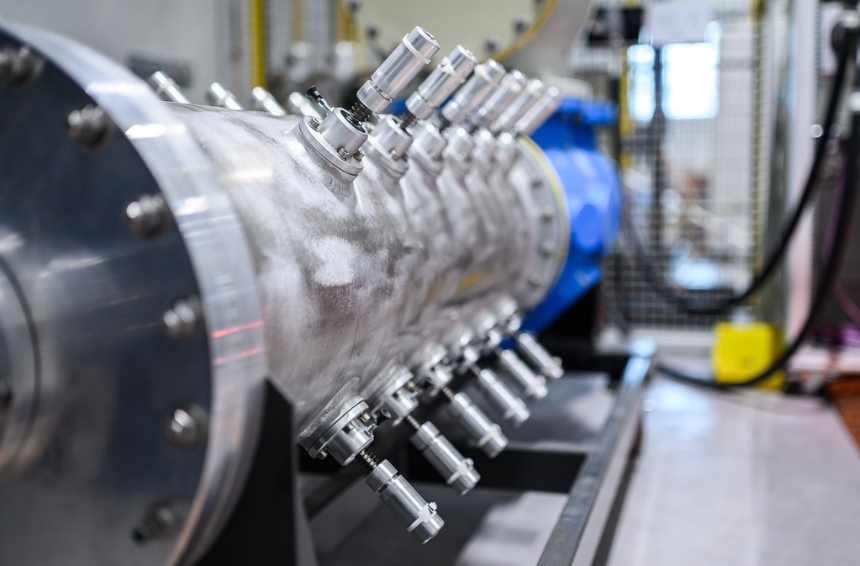

We measure the electrical parameters of solid, liquid and gaseous insulation with advanced methods in order to feed desktop design works including CAD. Some of our test benches have been developed in-house to respond to advanced technical challenges such as dielectric interfaces design and DC specificities.

Advanced electrical characterisation includes:

Dielectric spectroscopy analysis

Extract the main dielectric properties (dielectric constant, tanδ) of a material, as a function of frequency.

DC conductivity (bulk & surface)

A range of in-house set-ups to measure DC conductivity and its dependency on electrical field stress, temperature, pressure, humidity conditions and solid/gas interfaces.

Space charges (PEA)

The pulsed electro-acoustic (PEA) method is a non-destructive space charge measurement method used to characterise space charge behaviour inside solid insulation materials…

Dielectric & ageing testing

We perform special dielectric and ageing tests on material samples and reduced-scale prototypes to ensure the dielectric insulation performs reliably throughout the entire lifecycle of electrical equipment. Early stage testing is used to set design criteria for final electrical equipment.

These tests include:

- thermal and electrical ageing tests,

- various DC and AC tests (up to 100kHz),

- breakdown tests in various conditions,

- partial discharge tests.

Where needed, SuperGrid Institute designs test benches adapted to complex insulation challenges and implements suitable monitoring to execute the most relevant testing procedure.