Advancing hydropower innovation: presenting our hydraulic test results to the BILASURF consortium

When working on a European project, hosting the consortium at your place is a big step! We were delighted to welcome on the 15th– 16th December, the 10 project partners of BILASURF to our headquarters to present the results of the tests carried out on our hydraulic platform. Two phases of testing were carried out successively between 2024 and 2025, first on simplified profiles and then on a reduced real scale model of a Francis turbine.

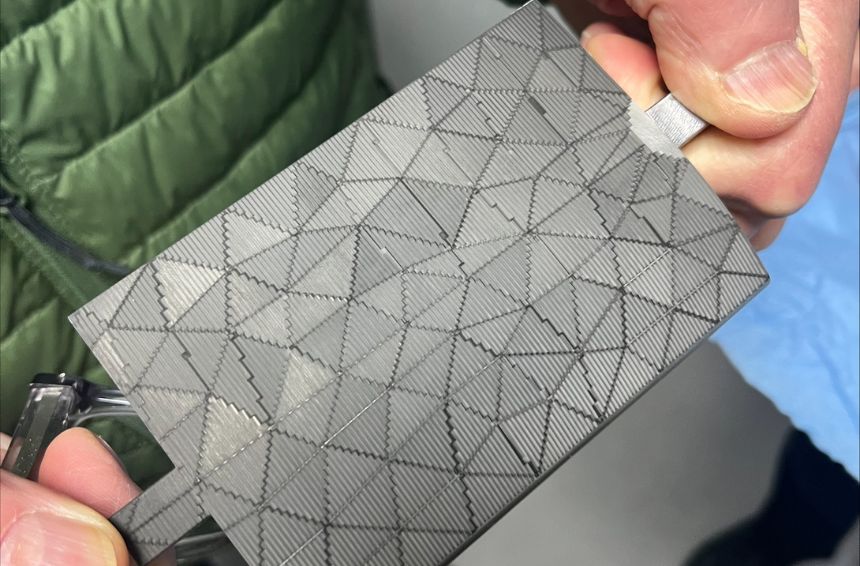

The BILASURF project is entering its final phase! Coordinated by CEIT, this European project involves developing a laser micro-engraving process and applying it to the surfaces of turbine blades (hydraulic and HVAC) in order to reproduce the effect of shark’s skin (BILASURF – Bio-inspired laser functionalisation of complex 3D industrial surfaces).

Over a period of 36 months, the 10 partners set themselves the goal of developing and integrating a high-throughput laser functionalisation process for complex 3D surfaces using custom-designed bio-riblets (a coating that mimics shark skin) – which will reduce friction and improve the environmental footprint of the parts.

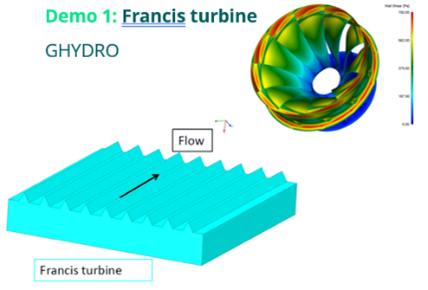

Influence of riblets on the behaviour of a hydraulic turbine

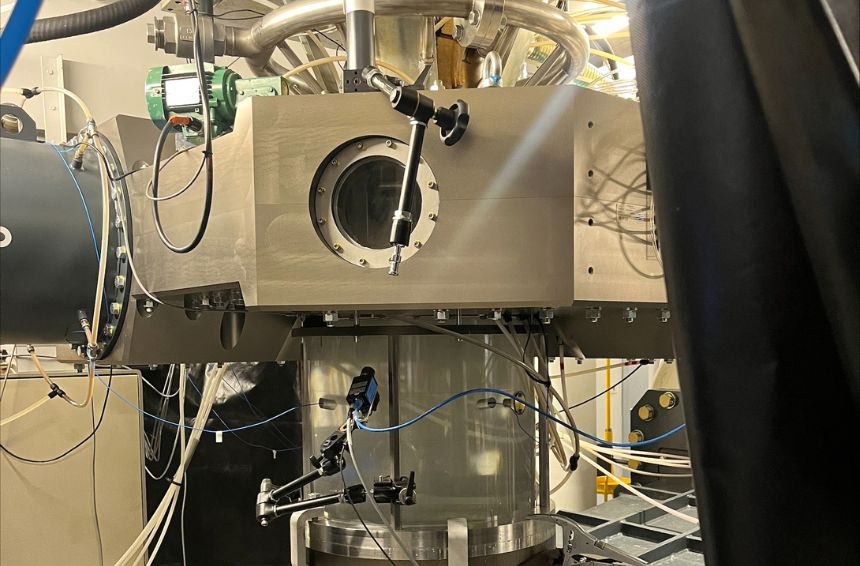

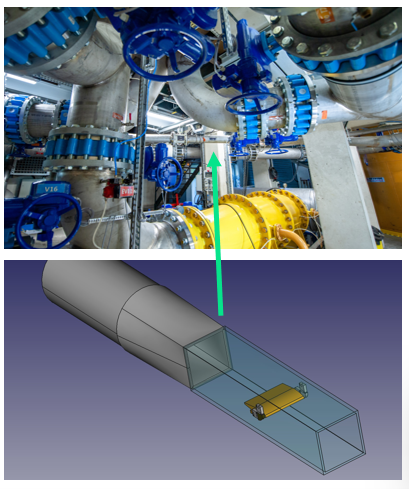

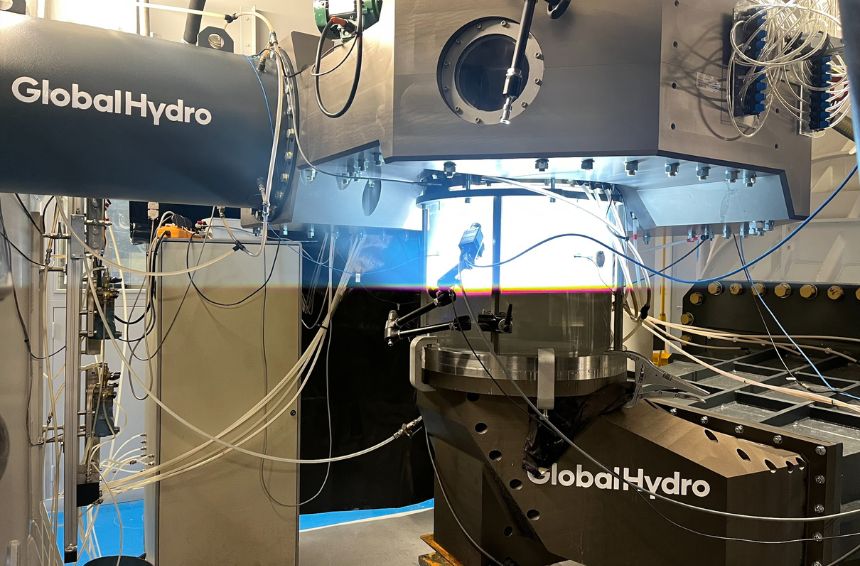

In this project, SuperGrid Institute Hydropower is overseeing the assessment of the influence of riblets on the behaviour of a hydraulic turbine, conducting tests on our hydraulic machines test platform (IEC 60193) in Grenoble.

“An initial phase of testing took place in 2024, using simplified profiles, explains Jean-Pierre Payre, project manager for SuperGrid Institute Hydropower. Thanks to our low flow line we were able to test the behaviour of hydraulic wicket gate.”

This configuration is located in the low-flow measurement section of the SuperGrid Institute’s IEC 60193 hydraulic platform. This addition enables dual flow measurement, with a 0.2% precision, without it affecting its normal operation.

“During the summer of 2025, we then received and assembled a complete scale turbine model on our platform, in order to conduct comparative tests with and without laser engraving to analyse the effect on efficiency and cavitation, continues Jean-Pierre Payre. This first testing phase took place in September 2025 and we are very pleased to have presented the results to the consortium members.”

Tests on the reduced scale model of our project partner, Global Hydro.

Success of this consortium meeting

All members of the consortium met at the SuperGrid Institute’s Hydropower headquarters in Grenoble, the 15th and 16th of December 2025. We were able to present the results of our tests with the reference model. These two days were a great success with very constructive discussions about the project and its results!

“We are delighted to contributing to this innovative project. Working alongside high-level European partners illustrates the collective dynamic that drives us and strengthens our expertise. This collaboration gives us the opportunity to showcase our testing facilities and the expertise of our hydraulics team, while actively contributing to the advancement of innovation at European level.”

Sylvain Grillet, leader of the hydraulic departement at SuperGrid Institute.

The project still has a few months before submitting its findings in spring 2026.